The Fiber That Makes the Difference: Why LYCRA® Commands Premium Positioning

Image Credit: © The Lycra Company

As apparel sourcing and product directors know, fiber selection isn't just a technical specification—it's a brand promise. And in today's competitive activewear market, the difference between LYCRA® and generic spandex directly impacts your brand's positioning, customer loyalty, and ultimately, your margin sustainability.

Here's what your customers don't see, but absolutely feel: the molecular engineering behind your garments.

Why Fiber Choice Determines Brand Perception

When your customers invest in activewear, they're not just buying comfort—they're buying durability, performance consistency, and the confidence that their investment will last. Brands that source premium fibers build customer lifetime value. Brands that compromise on fiber specifications get caught in a race to the bottom on price.

This matters for your supply chain strategy. Generic spandex requires you to optimize for lower price points, which means tighter margins and more pressure to scale volume. Premium fibers like LYCRA® allow you to build brand equity and command sustainable margins—if you know how to communicate that value.

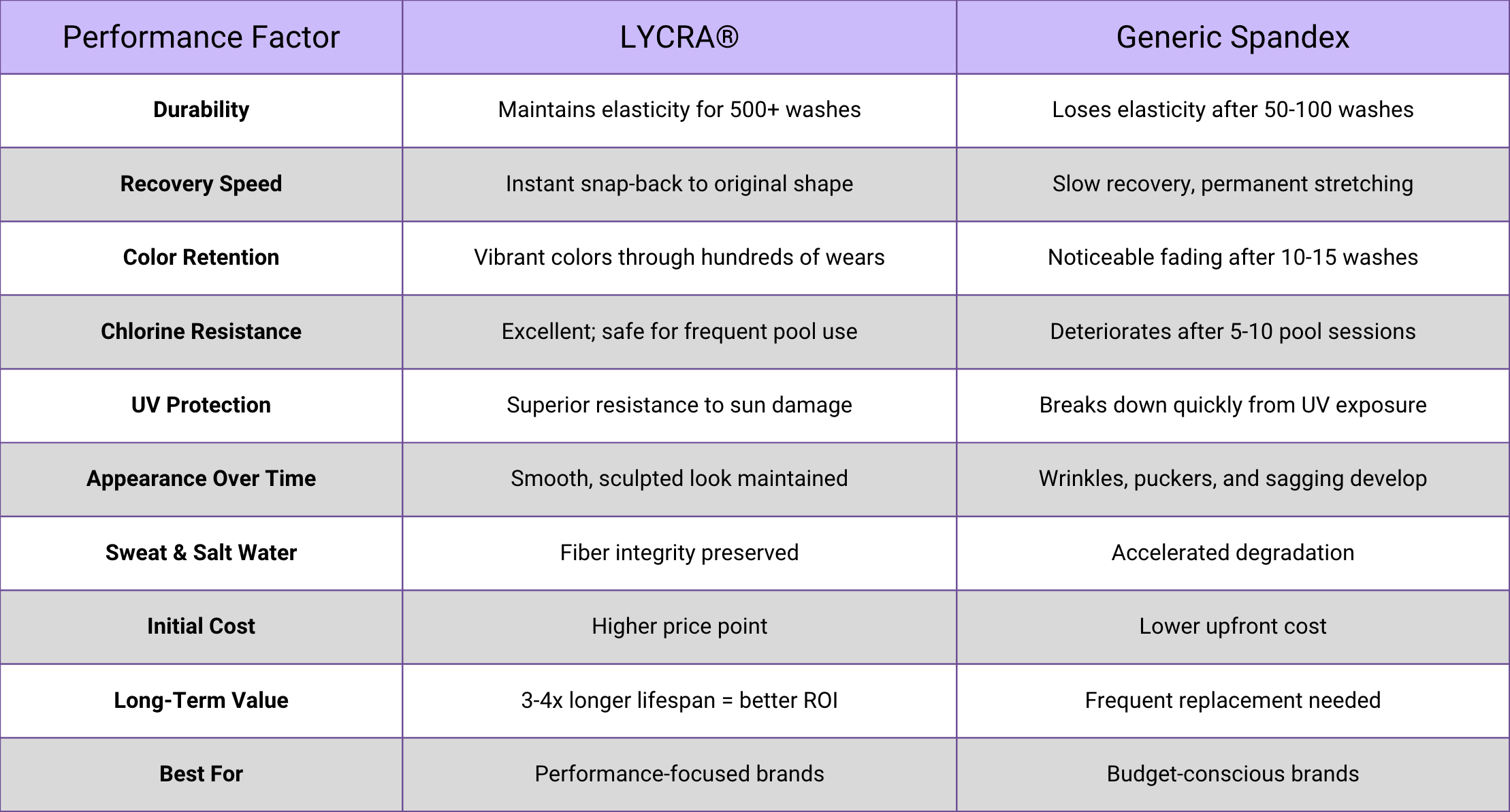

The Performance Reality Your Sourcing Team Should Know

This isn't theoretical. These metrics directly translate to your product roadmap, pricing strategy, and competitive positioning.

What This Means for Your Supply Chain Decisions

Margin Sustainability: Brands using LYCRA® can hold 30-40% higher retail price points while justifying cost. Generic spandex forces you into constant promotional cycles to move inventory.

Customer Retention: LYCRA® garments maintain performance through the lifecycle of use. This means fewer returns, better reviews, and higher repeat purchase rates. Generic spandex shows visible wear within a season, driving customer dissatisfaction and social media friction.

Quality Control Simplicity: LYCRA® is a standardized, engineered fiber. Your QA processes are more predictable. Generic spandex varies significantly between suppliers, requiring tighter testing protocols and creating supply chain unpredictability.

Differentiation Opportunity: In a crowded market, fiber choice is one of the few tangible ways to differentiate beyond design. A product director can identify LYCRA® in the product description and create a competitive moat that's difficult for fast-fashion competitors to replicate quickly.

Image Credit: © The Lycra Company

The Supply Chain Expert Perspective

Here's what we see working with brands across the activewear spectrum: the most successful players—the ones growing at 25%+ annually—make intentional fiber choices aligned with their brand positioning.

They're not asking "What's the cheapest spandex?" They're asking: "What fiber choice allows us to deliver on our brand promise while maintaining margin health?"

This requires partnering with manufacturers and sourcing experts who understand the fiber market, can access premium materials reliably, and can help you navigate the trade-offs between cost, performance, and positioning.

For ready-to-launch collections: LYCRA® integration signals quality to retailers and direct consumers. Your time-to-market advantage is amplified when you're launching with fiber credentials already built in.

For custom ODM/OEM projects: Fiber selection early in the design phase—not as an afterthought—determines your product's performance ceiling and your brand's long-term margin strategy.

For inventory-light operations: Choosing premium fibers reduces SKU proliferation because customers keep garments longer. You need fewer replacement units in inventory. Your supply chain becomes more efficient.

The Question Every Product Director Should Ask Their Manufacturer

Before your next production run, ask: "What fiber are we using, and why? And if we upgraded the fiber spec, what would that do to our cost, our retail positioning, and our customer lifetime value?"

The answer often surprises brands. Many manufacturers default to cheaper fibers without ever exploring whether a premium fiber shift could unlock margin improvements that offset the raw material cost increase.

Coming Soon: Creora vs LYCRA® — Navigating Premium Fiber Options

As brands invest in quality positioning, the fiber landscape is becoming more complex. Premium alternatives like Creora are entering the market with compelling value propositions. We're preparing a detailed comparison to help sourcing and product teams make informed fiber decisions aligned with their specific brand strategy.

Want to discuss fiber strategy for your next collection? Our supply chain consulting team has guided 150+ brands through fiber selection, manufacturing optimization, and margin-building sourcing decisions. Connect with us